POINT

- It was discovered that single-crystals, which are generally considered to transfer heat more easily, do not transfer heat more than polycrystals.

- The natural superlattice structure with a period of several nm significantly reduces heat conduction in the single-crystals.

- Achievements that provide great guidance for designing low thermal conductivity materials.

ABSTRACT

An international collaborative research group consisting of Assistant Professor Hai Jun Cho and Professor Hiromichi Ohta of the Research Institute for Electronic Science, Hokkaido University, and research institutes in Japan and overseas have discovered that heat conduction in single-crystals is significantly reduced more than polycrystals by introducing the superlattice structures with a period of several nm.

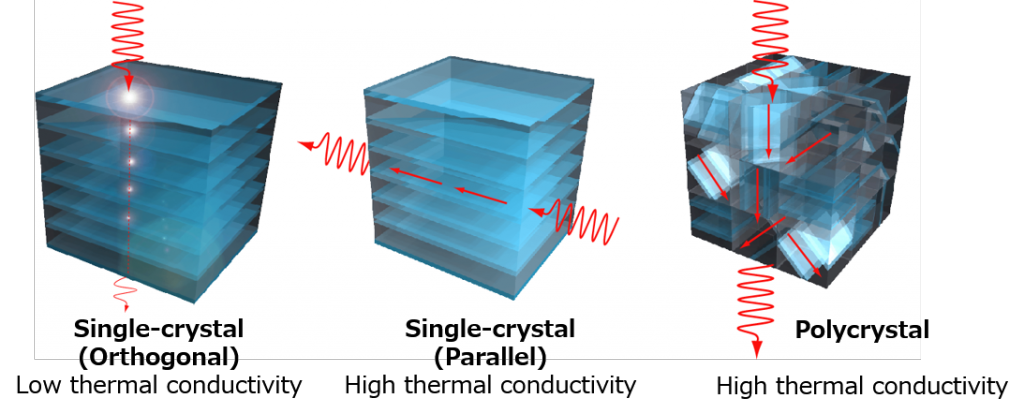

The heat conduction of electrically insulating ceramics occurs due to the propagation of quantized atomic vibrations (phonon). Therefore, the heat conduction is greatly attenuated at the crystal interface. In general, polycrystals with randomly oriented crystals contain many interfaces. Hence polycrystals exhibit lower thermal conductivity than single crystals. The research group fabricated a single-crystal thin film having a “superlattice” structure in which two types of components are stacked with a period of several nm, and compared the thermal conductivity in the directions orthogonal to and parallel to the superlattice. They also compared it with the thermal conductivity of polycrystals.

As a result, they found that the thermal conductivity in the direction orthogonal to the superlattice is lower than that of polycrystals, even though they are single-crystals. This finding suggests that the layered boundaries between different components in a single crystal significantly reduce heat transfer, and is expected to provide a great guide for designing low heat transfer materials.

The research results were published in Advanced Materials Interfaces on February 16, 2021 Japan time.

Information of the paper

| Title | Anomalously Low Heat Conduction in Single-Crystal Superlattice Ceramics Lower than Randomly Oriented Polycrystals |

| Authors | Hai Jun Cho1, Yuzhang Wu2, Yuqiao Zhang1, Bin Feng3, Masashi Mikami4, Woosuck Shin4, Yuichi Ikuhara3, Yu-Miin Sheu5, Keiji Saito6, Hiromichi Ohta1(1Research Institute for Electronic Science, Hokkaido University, 2Graduate School of Information Science and Technology, Hokkaido University, 3Institute of Engineering Innovation, The University of Tokyo, 4National Institute of Advanced Industrial Science and Technology, 5Center for Emergent Functional Matter Science, National Yang Ming Chiao Tung University, 6Department of Physics, Keio University) |

| Journal | Advanced Materials Interfaces |

| DOI | 10.1002/admi.202001932 |

| Publication date | February 16th, 2021 |

【Background】

Low thermal conductivity ceramics, which have low thermal conductivity, are important materials as thermal barrier coating agents for heat-resistant materials. The heat conduction of ceramic, which is an electrical insulator, occurs due to the propagation of quantized atomic vibrations. Hence polycrystals exhibit lower thermal conductivity than single-crystals. In order to further reduce the thermal conductivity of ceramics, a “superlattice” structure in which multiple ceramics are laminated at a period of several nm is useful, but it is necessary to alternately stack several nm each by an ultra-precise thin film fabrication method. There was a problem that it was not practical because it was not suitable for large areas and it took time.

【Approach】

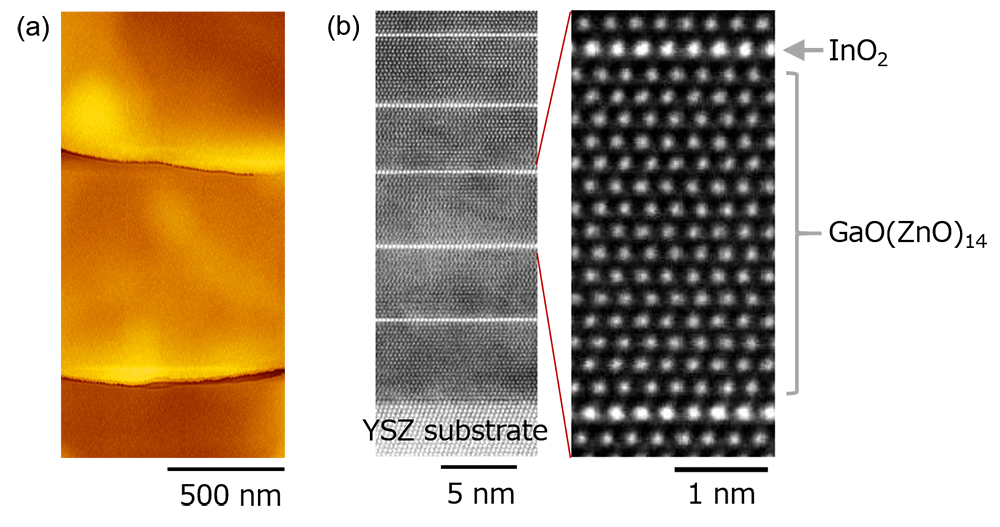

The research group focused on InGaO3(ZnO)m(m is an integer), a ceramic that has a structure in which two types of components are stacked in a period of several nm called a crystal-specific “natural superlattice.” The research group fabricated InGaO3(ZnO)m single-crystal thin films with various m-values by a method called the reactive solid-phase epitaxial growth method (Fig. 1). They measured the thermal conductivity in the directions orthogonal to and parallel to the superlattice. In addition to the comparison, they also compared the thermal conductivity of polycrystals whose crystal directions are not aligned.

【Results】

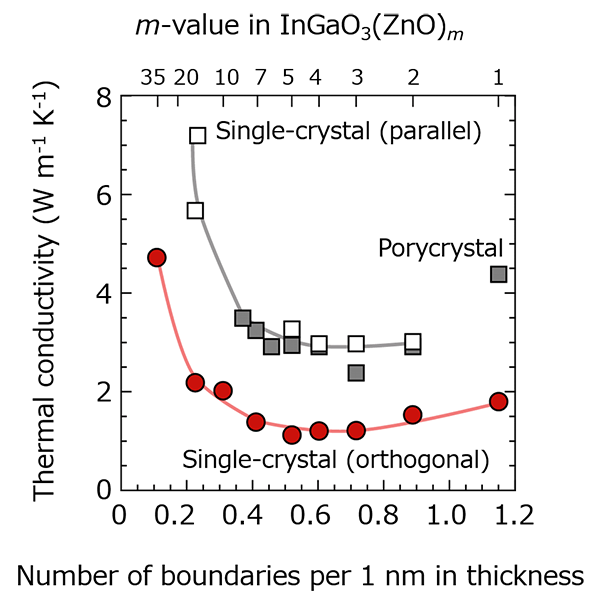

First, the thermal conductivity (room temperature) of the prepared InGaO3(ZnO)m single-crystal thin film was plotted against the number of boundaries per 1 nm in thickness (Fig. 2). The thermal conductivity in the orthogonal direction of the superlattice is extremely small (about 1 W m-1 K-1) when there are 0.5 to 0.6 boundaries per 1 nm of thickness. The behavior parallel to the superlattice and polycrystals are almost the same, but the minimum value is about 3 W m-1 K-1. Surprisingly, the thermal conductivity in the direction orthogonal to the superlattice is only 1/3 that of polycrystals, indicating that it exhibits low thermal conductivity.

In the direction orthogonal to the superlattice, the thermal conductivity is attenuated at the boundary between the InO2 layer and the GaO(ZnO)m layer. Therefore, it shows low thermal conductivity even though it is a single-crystal. In the direction parallel to the superlattice, there is no attenuation of heat conduction due to the boundary, and it shows high thermal conductivity. The thermal conductivity of polycrystals is almost the same as the thermal conductivity in the direction parallel to the superlattice (Fig. 3).

【Future prospect】

This finding suggests that the layered boundaries between different components in a single-crystal significantly reduce thermal conductivity. This finding would be a guideline for designing low thermal conductivity materials as thermal barrier coatings such as heat resistant materials.

【Acknowledgements】

This research was supported by Grants-in-Aid for Scientific Research A (17H01314) and Grants-in-Aid for Innovative Areas (19H05791 and 19H05788) from the Japan Society for the Promotion of Science (JSPS). A part of this work was also supported by the “Nanotechnology Platform” (12024046) of the MEXT (B.F. and Y.I.). Y.Z. was supported by International Research Fellow (19F19049) from the JSPS. Y.M.S. acknowledged Taiwan Ministry of Science and Technology (107-2628-M-009-004-MY3), and the Center for Emergent Functional Matter Science of National Chiao Tung University from The Featured Areas Research Center Program within the framework of the HESP by the Ministry of Education in Taiwan. H.J.C. acknowledges the support from Nippon Sheet Glass Foundation for Materials Science and Engineering. Y.W. was supported from China Scholarships Council (201908050162). A part of this work was supported by Dynamic Alliance for Open Innovation Bridging Human, Environment and Materials, and by the Network Joint Research Center for Materials and Devices.